The Wool Wire | November 24, 2025

Improving upon the methane measure, clean keratin extraction, wool in construction, British Wool turns 75, and science uses wool to replace plastic

News snippets from the wool world

Hello, my friends!

This week, we celebrate some geekier stories that highlight the enormous potential of wool for everything from insulation and furnishings to 3D printing. But first, there's the matter of gathering deeper data on wool's environmental footprint beyond methane alone—something sheep and other grazing ruminants produce.

In New Zealand, they're doing just this. The goal is to boost use of New Zealand's abundantly available strongwool in the construction industry, which already accounts for 40% of all methane emissions.

Initially...

Measured against 2030 climate change targets, methane emissions mean 1kg of wool has a marginally larger environmental footprint than nylon and polyester.

However...

Further research shows that the pecking order dramatically changes in favour of wool when quantifiable on-farm nature-enhancing initiatives are included such as wetland and biodiversity restoration – elements missing from the initial data.

Let's continue the research so we can get more wool into our buildings.

Tapping the untapped

Speaking of getting wool into our buildings, I enjoyed this article praising wool's untapped potential for what the author describes as "the built environment." It's from the design and architecture magazine Metropolis, and it covers everything from recycling to insulation.

This renewable, carbon-munching material could play a larger role in protecting the health of humans and the planet. No man-made fiber can rival wool’s ability to filter volatile organic compounds from the air while regulating temperature and moisture and being naturally flame resistant and biodegradable.

Hear hear!

A new way to turn waste into gold

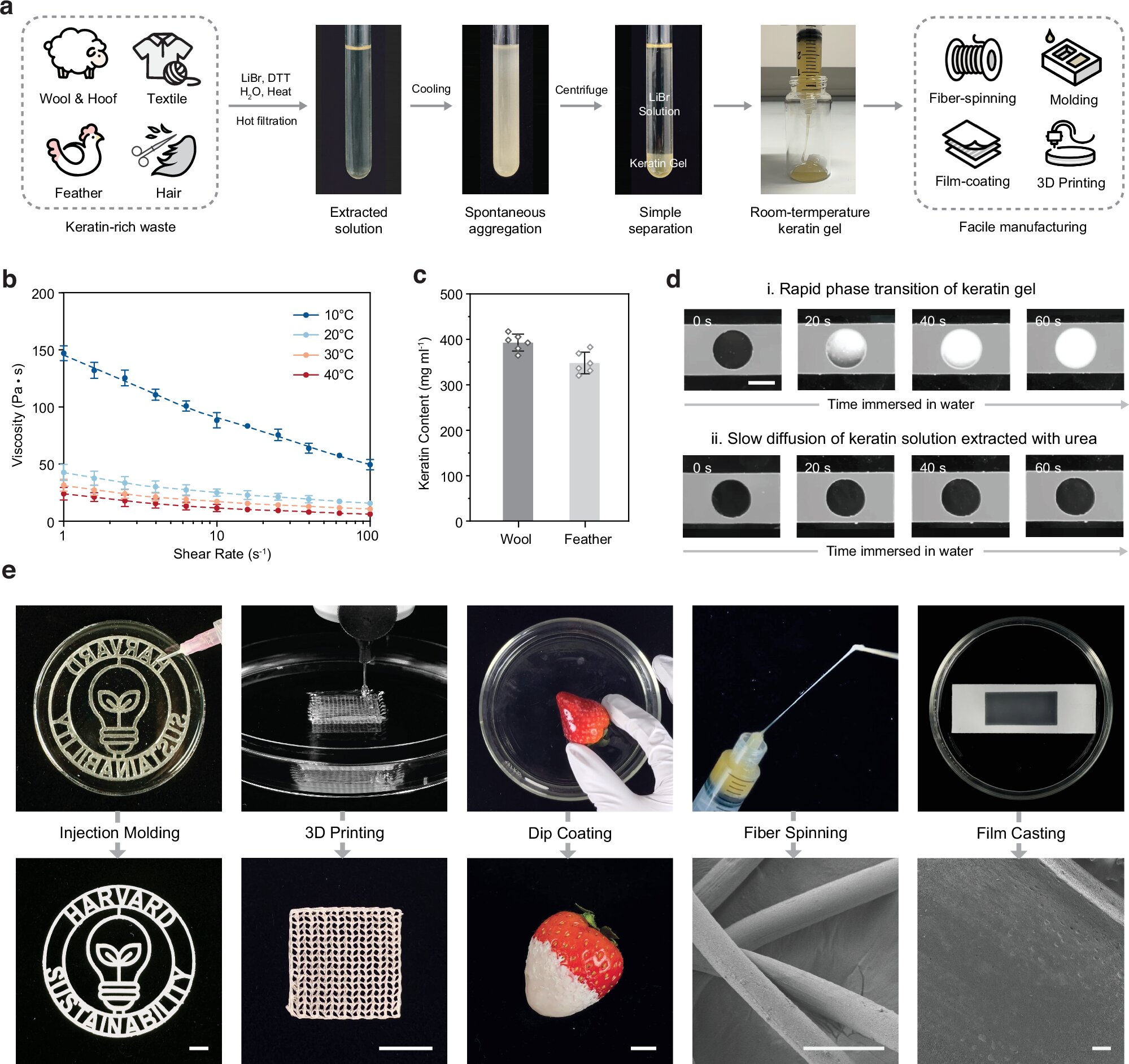

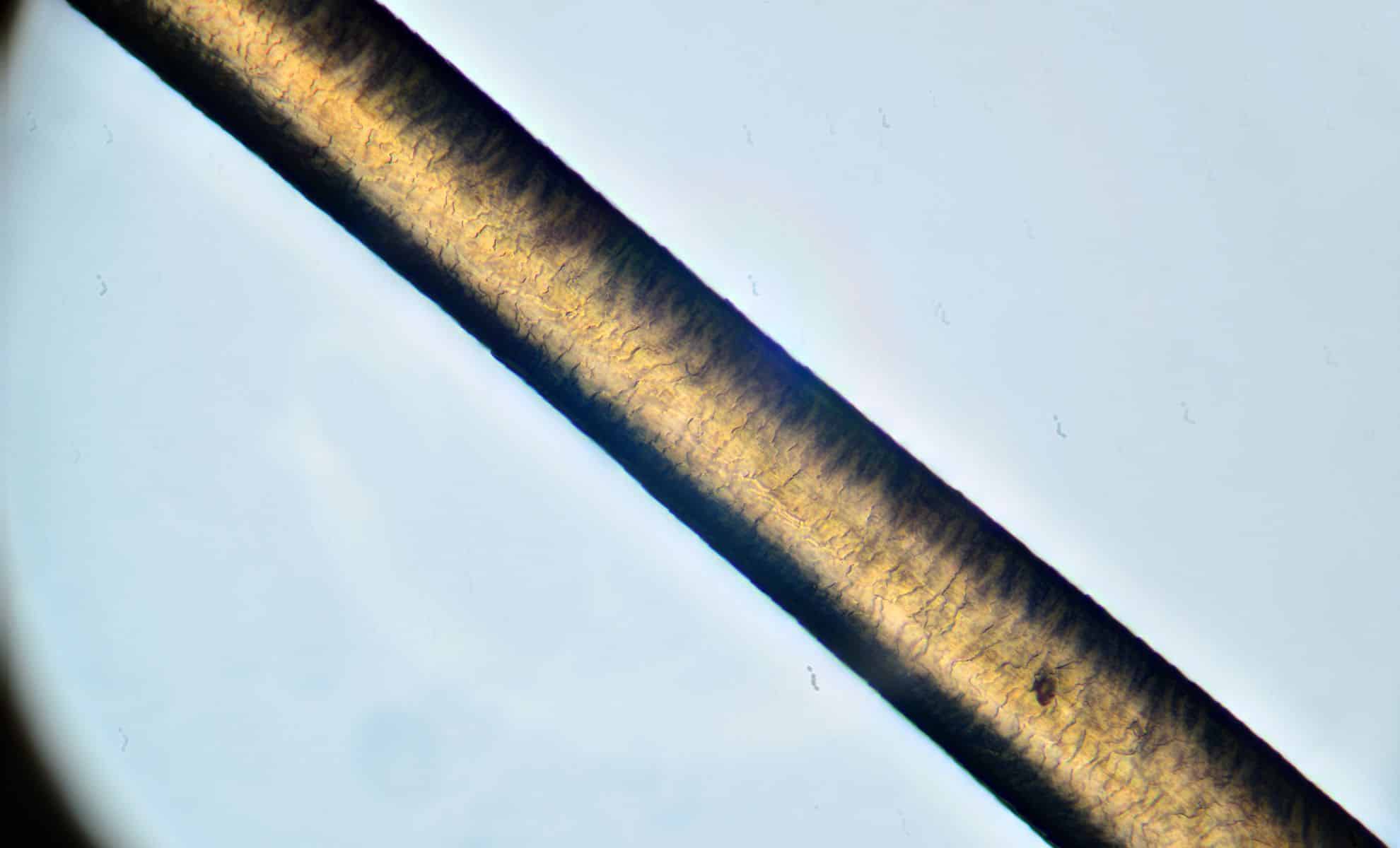

Each year, the textile and meat-processing sectors generate billions of tons of keratin-rich waste materials, including feathers, wool, and hair. Extracting that keratin generally requires harsh chemical solvents and processes that consume large amounts of energy—which is what makes this next story so exciting.

Researchers at Harvard's John A. Paulson School of Engineering and Applied Sciences have discovered that a salt compound called lithium bromide changes the structure of surrounding water molecules, causing the keratin to almost effortlessly "unfold" all by itself.

And why is this exciting? We turn to a subsequent story for an explanation.

The texture of this new material is shear-thinning—which means it moves when pushed but firms up when still. That makes it perfect for things like 3D printing, molding, and fiber spinning. Basically, all that hair and feather waste could be turned into recycled textiles, bioplastics, or medical materials.

Perhaps most notably, the lithium bromide solution used in the process is completely reusable, enabling a closed-loop recycling system. That translates into reduced waste, lower environmental impact, and significant potential for scaling up in industrial settings.

Can you imagine a "plastic" that's actually made of the keratin from sheep's wool?

From high to low to....?

Published on the occasion of the British Wool Marketing Board's 75th birthday in September, this next article takes a concise look back at wool's trajectory, from its heights in Medieval society to its low, low lows by 2020.

Sheep shearing was king in the middle ages, writes Lotte Brundle, but the rise of synthetic fibres put the industry in a woolly position. How is it faring now?

And how is wool faring now? The facts may be familiar, but this article tells a story that's worth revisiting—especially as we head into the consumer spending blitz surrounding Black Friday.

Who wouldn't want a sweater that lasts a lifetime?

On that note, I'll let you go. Thank you, as always, for your readership and your support.

Until next time,

Clara

The Wool Channel Newsletter

Join the newsletter to receive the latest updates in your inbox.